Artificial intelligence (AI) in manufacturing has rapidly evolved from an experimental technology into a powerful force driving industrial growth and innovation.

As manufacturers worldwide strive to maintain a competitive edge, AI solutions are becoming indispensable for optimizing operations, improving quality, and reducing costs.

In this article, we explore the impact, benefits, and challenges of AI in manufacturing, along with key technologies and techniques that will shape the industry in 2025.

1

Impact of AI in Manufacturing

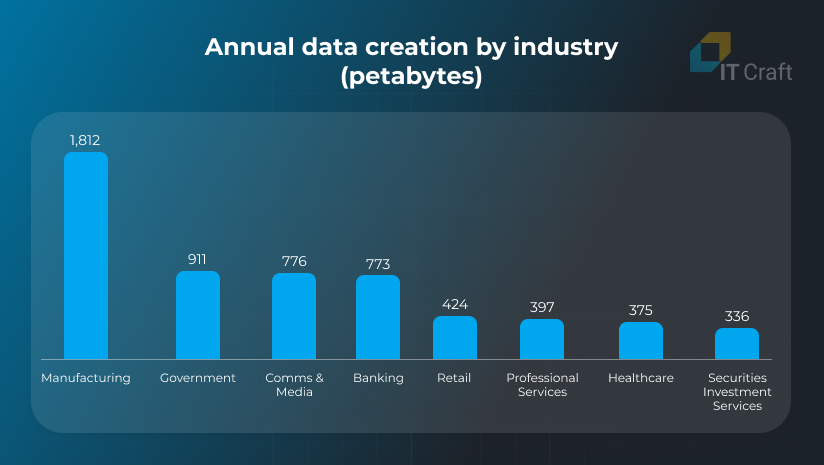

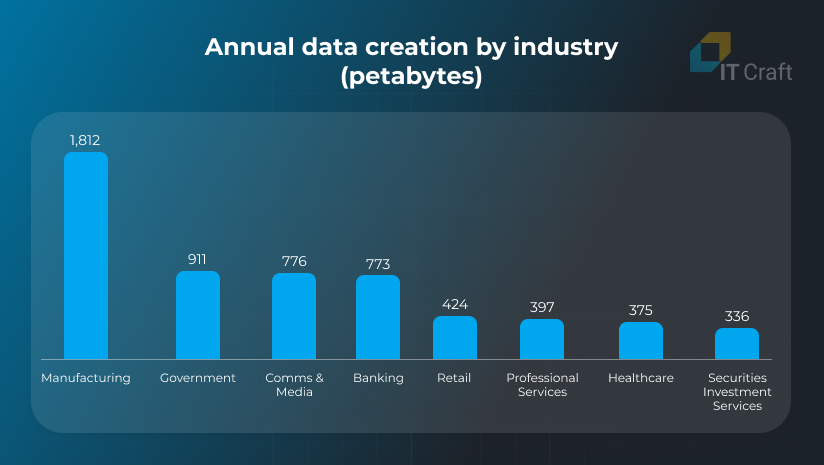

According to a Deloitte survey, manufacturing is the leading industry in terms of data generation. The enormous amount of data produced by companies in this sector demonstrates manufacturing’s considerable influence on the overall data ecosystem.

To effectively manage and interpret this vast amount of data, manufacturers need to embrace AI technologies.

A recent survey by VentureBeat shows that 26% of companies are using generative AI to improve decision-making. Furthermore, 66% of manufacturers who have adopted AI in their daily operations report an increasing dependence on the technology, highlighting the growing trend of AI adoption in the manufacturing sector.

In 2025, manufacturers will rely heavily on AI for:

- Predictive Maintenance: AI-driven algorithms can analyze machinery data in real time, predicting equipment failures before they occur, lowering costs, and reducing downtime.

- Quality Control: AI-based vision systems can inspect products faster and more accurately than human inspectors, ensuring a higher level of consistency and reduced waste.

- Supply Chain Optimization: AI helps manufacturers anticipate demand fluctuations, optimize inventory levels, and streamline logistics, leading to faster production cycles and improved customer satisfaction.

2

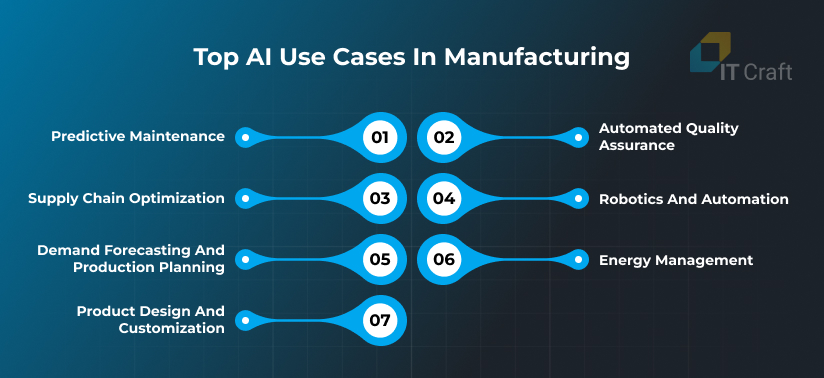

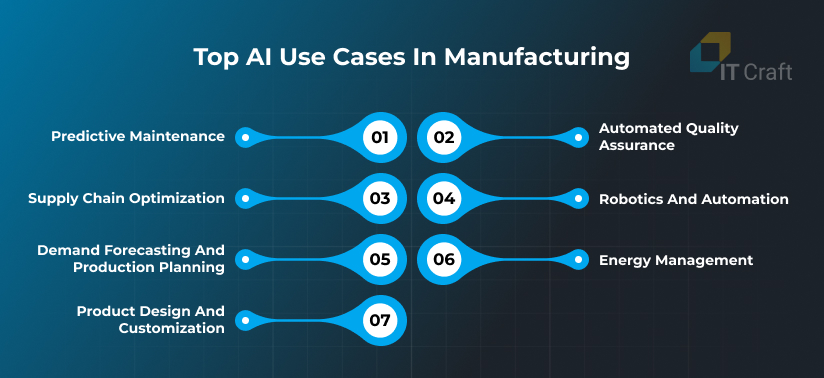

Top AI Use Cases in Manufacturing

AI applications in manufacturing are wide-ranging and continue to expand as new technologies emerge. Below are some of the most impactful use cases manufacturers should focus on in 2025:

Predictive Maintenance

Predictive maintenance uses real-time data to forecast when maintenance is needed, allowing manufacturers to perform maintenance before equipment fails. This approach helps avoid unexpected breakdowns, reduces downtime, and extends the lifespan of machinery, resulting in cost savings and improved efficiency.

Automated Quality Assurance

AI-driven visual inspection systems can detect product defects with greater accuracy and speed than human inspectors, ensuring better quality control and reducing production errors.

A prime example of AI-driven quality control in manufacturing is seen at Foxconn, a leading electronics producer. Foxconn has enhanced its quality control systems by integrating AI and computer vision technologies into its production processes. These AI systems can rapidly and accurately detect defects in electronic components through image and video analysis, ensuring that products consistently meet stringent quality standards.

AI in quality control boosts production efficiency and precision, enabling companies like Foxconn to deliver high-quality products at scale in the fast-paced electronics industry.

Supply Chain Optimization

AI helps companies predict demand, manage inventory, and optimize supply chains, enabling more efficient production processes and reduced waste.

Robotics and Automation

AI-driven robotics are transforming factory floors by automating repetitive and labor-intensive tasks. Robotic systems work alongside human operators to enhance production speed and consistency, while reducing the potential for human error.

This leads to higher throughput and a more efficient workforce that can focus on more complex tasks.

Demand Forecasting and Production Planning

AI algorithms are being used to more accurately predict market demand, helping manufacturers adjust their production schedules accordingly.

This ensures better alignment between supply and demand, minimizes excess inventory, and reduces lead times, allowing companies to respond quickly to market changes.

Energy Management

AI can analyze energy consumption patterns across production lines and identify areas for improvement in energy efficiency.

By optimizing energy use in real time, manufacturers can lower costs, reduce their carbon footprints, and contribute to sustainability goals without compromising productivity.

Product Design and Customization

AI is also making waves in the realm of product design by helping manufacturers create more innovative, high-performing products faster.

Through AI-driven simulations and predictive analytics, manufacturers can test designs virtually before prototyping, saving time and reducing development costs. Additionally, AI enables mass customization, tailoring products to individual consumer preferences at scale.

3

Benefits of AI in Manufacturing

The benefits of adopting AI in manufacturing extend far beyond simple automation. In 2025, AI will offer manufacturers the following advantages:

By automating routine tasks and optimizing complex processes, AI can drastically reduce operational inefficiencies.

Predictive analytics and machine learning algorithms can identify inefficiencies and suggest cost-saving measures that lead to significant financial benefits.

AI-driven insights provide actionable data, enabling faster and more accurate decision-making.

AI systems can adapt to changing production needs, allowing manufacturers to scale their operations quickly and efficiently.

4

AI Implementation Process

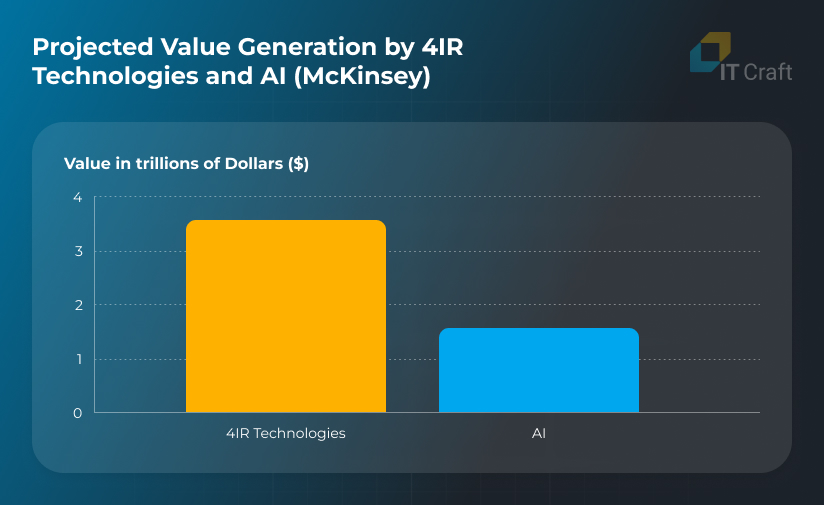

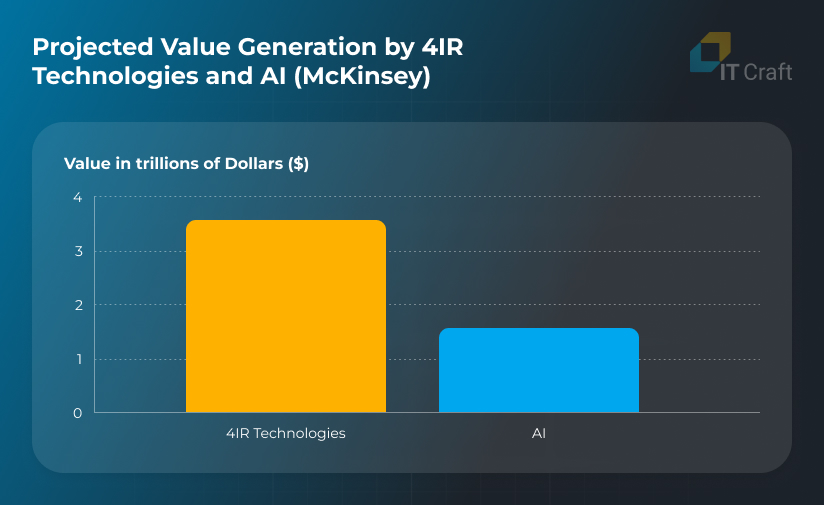

According to McKinsey, Fourth Industrial Revolution technologies could generate up to $3.7 trillion in value by 2025. AI alone has the potential to contribute between $1.2 trillion to $2 trillion in value for manufacturing and supply chain management.

Implementing AI in manufacturing requires careful planning and execution to ensure the technology is integrated effectively. Key steps in the AI implementation process include:

- Assessing Business Needs: Manufacturers must first determine which areas of their operations will benefit the most from AI.

- Collecting and Managing Data: AI relies on vast amounts of data, so manufacturers need to ensure that they have robust systems in place for collecting and managing it.

- Running Pilot Programs: Before full-scale implementation, companies should run AI pilot programs to test the technology and make necessary adjustments.

- Scaling the Solution: Once proven effective, AI solutions can be scaled across the entire organization, driving greater efficiency and innovation.

5

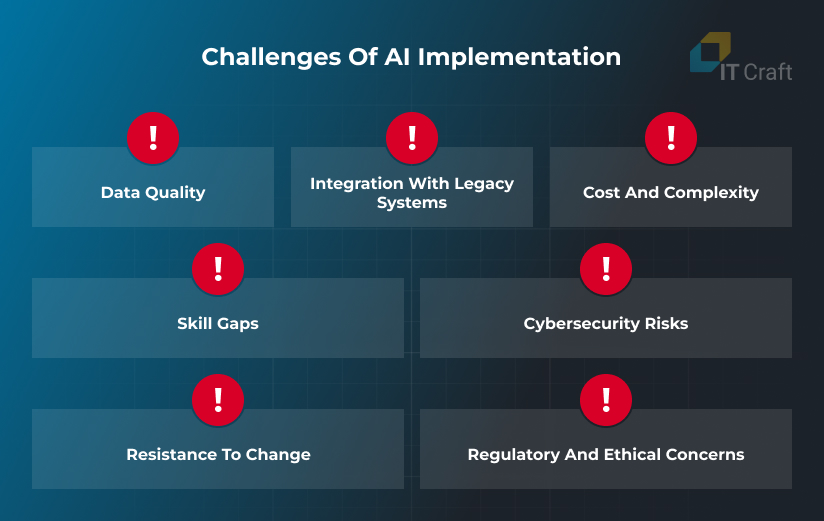

Challenges of AI Implementation

While AI offers numerous benefits, its implementation in manufacturing is not without challenges. Key obstacles manufacturers face in 2025 include:

AI systems require high-quality, accurate data to function effectively. Poor data can lead to flawed insights and costly errors. Manufacturers often struggle with inconsistent or incomplete data, which can undermine AI’s potential.

- Integration with Legacy Systems

Many manufacturers still rely on outdated systems that are incompatible with AI. Integrating AI into these legacy systems often requires significant upgrades or custom solutions, adding complexity and increasing the cost.

Implementing AI is expensive, particularly for smaller manufacturers. The initial investment in AI technologies, along with the ongoing costs for maintenance and updates, can be prohibitive. Additionally, the complexity of deploying AI systems increases costs compared to traditional manufacturing processes.

Adopting AI requires skilled professionals in areas like machine learning and data analytics. Many manufacturers face a shortage of talent, which slows AI implementation and reduces its effectiveness. Upskilling existing employees or recruiting AI specialists is essential.

As manufacturers adopt AI, they face increased cybersecurity risks due to reliance on interconnected systems and data exchange. Strengthening cybersecurity measures is critical to protect AI systems from potential attacks.

Employees accustomed to traditional manufacturing methods may resist AI adoption, fearing job displacement or changes to their roles. To ensure a smooth transition, manufacturers must invest in change management and retraining.

- Regulatory and Ethical Concerns

AI implementation must also comply with data privacy regulations and ethical guidelines. This is essential to prevent legal issues and maintain trust.

6

AI in Manufacturing: Key Technologies and Techniques

Several key technologies and techniques are driving the adoption of AI in manufacturing, including:

- Machine Learning (ML): ML algorithms allow systems to learn from data and improve over time, providing manufacturers with better predictive capabilities and optimization solutions.

- Computer Vision: AI-powered computer vision systems enable machines to see and analyze visual information, enhancing quality control and automation efforts.

- Robotics: AI-driven robotics offer greater precision and flexibility in manufacturing processes, from assembly to packaging.

- Natural Language Processing (NLP): NLP enables machines to understand and respond to human language, improving human–machine collaboration and streamlining factory communication.

7

How AI Will Change Manufacturing

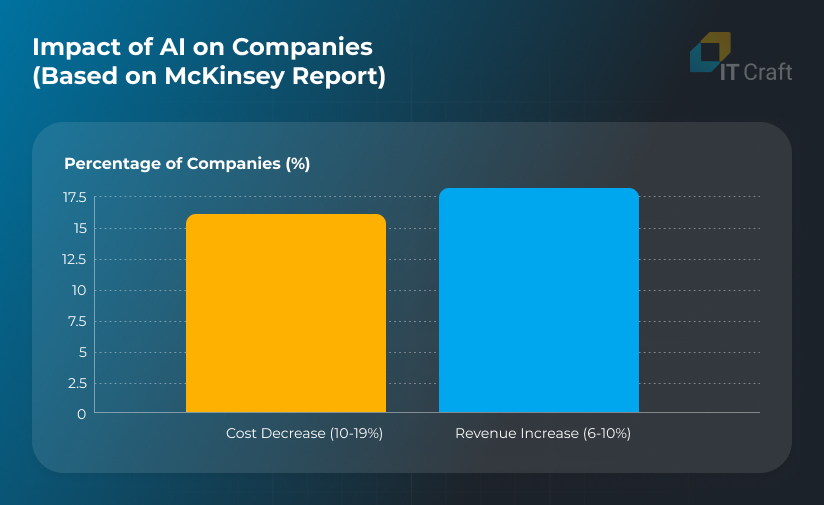

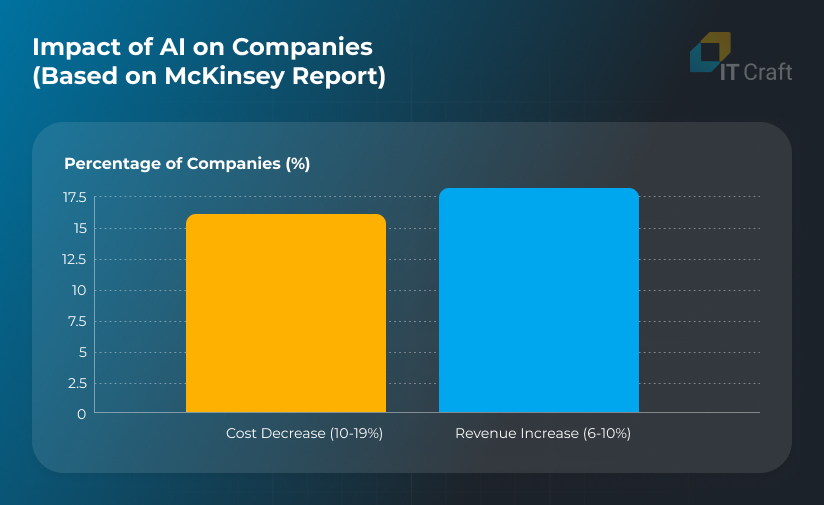

As reported by McKinsey, companies implementing AI have experienced both cost reductions and revenue growth. Of those surveyed, 16% observed a 10–19% decrease in costs, while 18% reported a 6–10% rise in total revenue.

Increased Automation

AI will drive unprecedented levels of automation across manufacturing processes, reducing reliance on manual labor. This shift allows manufacturers to:

- Reduce Operational Costs: By automating repetitive and labor-intensive tasks, manufacturers can reduce human labor costs and the potential for human error.

- Boost Production Speed: Automated systems powered by AI can operate around the clock without downtime, leading to faster production cycles and significantly increased output.

- Enhance Precision: AI-enabled automation offers unmatched precision in tasks such as assembly, welding, and packaging, which not only improves product quality but also reduces material waste.

- Improve Worker Safety: By taking over dangerous and physically demanding tasks, AI-driven robots and systems minimize the risk of workplace injuries, ensuring a safer environment for human workers.

With AI, factories will increasingly shift towards lights-out operations where minimal human intervention is required, further optimizing productivity and operational efficiency.

Smarter Factories

One of the most exciting prospects for AI in manufacturing is the rise of smart factories. These factories leverage AI, the Internet of Things (IoT), and machine learning to create self-optimizing production systems capable of:

- Real-time Decision-making: AI enables machines to communicate with one another and respond to production changes in real time. For example, if a machine detects a defect or issue, it can immediately adjust or notify other systems to prevent further errors down the line.

- Predictive Maintenance: Smart factories rely on AI to continuously monitor equipment health. Predictive analytics allows manufacturers to foresee and fix potential issues before they escalate into costly breakdowns, maximizing machine uptime and efficiency.

- Self-learning Processes: Smart factories can refine their operations over time through machine learning. By analyzing data from various sources, AI systems can identify inefficiencies and automatically implement improvements, leading to more streamlined processes.

- Energy Optimization: AI-driven smart factories can also optimize energy consumption by automatically adjusting power use based on real-time needs, leading to more sustainable and cost-effective operations.

As more manufacturers adopt AI, smart factories will become the norm, enabling businesses to achieve unprecedented levels of adaptability and responsiveness.

Customization at Scale

One of the biggest shifts AI will bring to manufacturing in 2025 is the ability to offer mass customization.

While manufacturers traditionally focused on mass production, AI will enable them to meet the growing demand for personalized products without sacrificing efficiency or increasing costs. AI will play a crucial role in:

- Flexible Production Lines: AI systems can adjust production lines in real time to accommodate different product specifications or customer preferences. Whether it’s modifying a product’s color, size, or features, AI will allow manufacturers to switch between custom orders quickly without interrupting the production flow.

- On-demand Production: With AI, manufacturers can efficiently shift to on-demand production models, where products are made to order. This approach minimizes inventory waste and allows for more precise production, though it may impact delivery speed compared to having pre-produced items in local warehouses or stores.

- AI-driven Design Customization: AI-powered design tools allow customers to create personalized products — whether that’s customized clothing, shoes, or electronics — by inputting their preferences directly into the system. These designs are then automatically integrated into the production process with minimal delay.

- Improved Supply Chain Management: AI enhances the flexibility of supply chains, ensuring manufacturers can quickly source and allocate materials based on customized orders. This level of real-time adjustment and resource allocation was previously unthinkable in traditional mass production models.

8

How IT Craft’s Custom AI Solutions Can Help You Achieve Manufacturing Excellence

At IT Craft, we specialize in developing custom AI solutions tailored to the unique needs of manufacturing businesses. Our team of experts can help you:

- Optimize Your Production Processes: We can help you streamline operations, reduce costs, and boost productivity by leveraging AI.

- Enhance Quality Control: Our AI-powered systems ensure your products meet the highest quality standards through advanced visual inspection techniques.

- Improve Decision-making: Our custom AI solutions give you access to real-time data and predictive insights, enabling faster and better decision-making.

Whether you’re looking to implement AI in a single process or across your entire organization, IT Craft is here to help you achieve manufacturing excellence in 2025 and beyond.

!

Conclusion

In 2025, AI is set to be a game-changer for the manufacturing industry, driving automation, enabling smart factories, and making mass customization achievable. Companies that adopt AI will see improved efficiency, cost savings, and the ability to meet evolving customer demands.

The key to success lies in thoughtful implementation and investment in both technology and workforce development. Manufacturers who embrace AI will lead the industry, while those who delay may struggle to stay competitive. The future of manufacturing is here, and AI is at its core.