Logistics software development is a crucial part of supply chain optimization in a world where deliveries happen every second. Companies must incorporate improvements quickly. Otherwise, little mistakes accumulate with disappointing results for both their customers and the companies themselves.

For instance, a third of businesses have sold items out of stock, resulting in delayed deliveries and lost customers. 25% of those customers who did not receive their order on time reported they would walk away and never return.

Let’s discuss the key considerations of optimization in supply chain management and how the right software implementation helps.

Step-by-Step Supply Chain Optimization

1. Foundation & Visibility

Map Your Current Supply Chain: An audit is always the first step; map out the entire flow structure from origin through consumption to return management to understand what matters the most.

Conduct a Supply Chain Audit: Next, take a granular look at your supply chain. This helps you identify blind spots and areas for improvement that you want to prioritize while working on strategic goals.

Define Clear Goals: Together with the project team, determine implementation goals and set measurable KPIs you plan to reach within a clearly defined timeline. These can include delivery accuracy, cost optimization, supply chain visibility, and others.

2. Planning & Strategy

Enhance Visibility & Integration: The project team designs a data flow that allows for end-to-end transparency, incorporating involved departments, partners, and/or suppliers.

Forecast Demand & Align Planning: Engineers can integrate historical data and trends to improve demand forecasts, which in turn will let you better balance planning and inventory management.

Build Flexible Capacity & Redundancy: Developers plan for agile up- and downscaling to ensure flexibility. They will help you create a scenario in case of disruptions, which you can quickly activate when those happen.

3. Execution & Technology

Leverage Technology & Automation: The project team implements automation functionality, adding it to your TMS, WMS, or ERP system, so that timely action will not be overlooked.

Optimize Key Areas: Stakeholders and developers focus on the areas where optimization brings the most significant value. It can be inventory, fulfillment, transportation, and sourcing.

Strengthen Partnerships: You can use implemented technology to improve collaboration and ensure your entire supply chain maintains high standards.

4. Continuous Improvement

Monitor & Measure At this step, your system collects data that you can use to measure KPIs for supply chain performance as well as stakeholders’ feedback.

Review & Refine: The collected information enables you to gain insights into further areas for improvement in the supply chain design and related process optimization.

Best Development Companies with the Strongest Portfolio of Projects for Supply Chain Optimization

1. IT Craft

A reputed technological vendor with strong capabilities in building and optimizing logistics software development solutions for supply chains of all complexities and 25 years of operations, IT Craft can be a great option for companies that are looking for a combination of technological expertise, understanding of supply chain challenges, and focus on long-term partnerships.

IT Craft developers do not just write code, they emphasize business outcomes and the positive effect of provided solutions on process visibility and efficiency. They know how to build and maintain data-heavy functionality for ERP, TMS, and CRM systems, ensuring long-term support of evolving supply chain needs through scalable and expandable codebase.

Services & expertise: custom supply chain solutions development, software consulting and digital transformation, supply chain software modernization and maintenance, system integrations, API development, DevOps and cloud optimization.

Technology stack: Laravel, Spring, .NET, Django, Flask, Node.js, React, Angular, Vue, Redux, Tailwind, TypeScript, React Native, Flutter, Kotlin, Swift, Ionic, MAUI, AWS, Azure, GCP, Digital Ocean, Docker, Jenkins, Ansible, Terraform.

Team size: 330+ experts.

Transportation Management System Development for MyCarrier

MyCarrier required an efficient solution for its idea of eliminating inefficiencies when managing truckloads. The envisioned system connects shippers and their customers, enabling both parties to make fully visible deliveries.

The IT Craft team developed an MVP from scratch, staying within the client’s time and budget limits. While user interest skyrocketed, proving the market demand for the product, the development team continued working on product expansion and transformation. It also ensured scalability and stability, as well as quick feature updates.

Results:

- MyCarrier TMS was named the leading TMS software by G2 platform.

- The client secured $36.8M in funding.

Read Case Study

Custom CRM system development for eLaundry

Initially, the owner of eLaundry had an unfinished software system. He wanted to manage on-demand laundry services for regular customers in Manhattan with its help. The IT Craft team took over the client’s project, improving, finalizing, and expanding the available system.

IT Craft engineers finalized the software solution, adjusting it to the exact client’s processes. They also helped the client with digital transformation once they decided to focus on business customers, such as cafés, restaurants, and hotels.

Results:

- The system enables complete visibility of employed processes across 10 departments, processing data in real-time and sending notifications to responsible managers.

- The business owner can track the revenue margins of each order using 50 client parameters to identify inefficiencies and improvement areas.

Read Case Study

Legacy ERP Software Transformation for FieldOne

The FieldOne system was used for coordination between field technicians and office managers, improving business processes inside service companies. The project once started as desktop software. It was losing its competitive edge after the mass adoption of smartphones and tablets, requiring a complete transformation.

The IT Craft team initially took over software maintenance. It switched to software transformation soon to get the client’s project back on track. The team completed seamless integrations with multiple systems for quick data exchange. Special emphasis was on app security and user data protection.

Results:

- The system enabled efficient communication between the back office and field teams.

- Eventually, Microsoft acquired the FieldOne system to increase its own bottom line.

Read Case Study

2. Leobit

Leobit specializes in end-to-end system development for supply chain management in addition to several other domains and can build a wide range of solutions, from web and mobile apps to embedded software.

The firm offers a proven track record of successful deliveries. Its programmers can handle advanced technologies that can be used for real-time data collection as well as complete complex integrations. Moreover, Leobit provides ISO certifications and GDPR/CCPA/OWASP compliance, addressing security and regulation concerns.

Services & expertise: custom supply chain management system development, TMS development, fleet management, web and mobile software development, software architecture design, app support and maintenance, AI development.

Technology stack: .NET, ASP.NET, Azure, WCF, Entity Framework, MAUI, Blazor, Angular, React, TypeScript, Ruby on Rails, Node.js, Python, Golang, Flutter, Swift, Kotlin, Heroku, C/C++, Tableau, Docker.

Team size: 170+ experts.

Top clients: American Financial Resources, Asprey Management Solutions, TrichoLAB, YUMI, Inventify.

3. Clockwise Software

Clockwise Software has accumulated deep expertise in working on complex projects for logistics, fleet management, and supply chain domains, having delivered 10+ supply chain projects out of an overall 200+ digital products. The company ensured seamless integration, helping clients with end-to-end visibility and optimization.

Clockwise Software engineers are praised for their PMI-aligned approach and clear communication that ensure timely deliveries of tailored solutions. The clients also highly value the company’s ability to provide quickly skilled developers via a staff augmentation model and integrate them closely into client teams.

Services & expertise: supply chain software development, fleet performance management software development, SaaS platform development, MVP development, ERP system development, data visualization.

Technology stack: React, Vue, Angular, Next.js, TypeScript, Prettier, Babel, Tailwind, Node.js, Laravel, Ruby, RESTful API, React Native, Kotlin, Swift, Jest, Mocha, Storybook, AWS, GCP, Azure, Cypress, Bitbucket, Jest.

Team size: 80+ experts.

Top clients: Foresolutions, Workerbee, Metacost, Premier Consulting, Cover Whale.

4. Q3 Technologies

Q3 Technologies is another renowned expert company offering end-to-end capabilities in delivering and maintaining logistics and supply chain platforms. The company offers a wide range of solutions that can be implemented across different parts of the supply chain, backed by a wide experience in successfully delivering client projects.

In particular, the firm’s engineers have practical knowledge in building cutting-edge enterprise-level solutions. They can also support legacy software landscapes. The clients highlight the company’s approachability, which allows for long-term cooperation.

Services & expertise: logistics and freight management, order management, WMS development, real-time route optimization, shipping logistics management, DataOps, web and mobile app development, legacy app modernization.

Technology stack: Java, Node.js, .NET, PHP, Python, Golang, Angular, React, Vue, React Native, Next.js, AWS, Azure, DigitalOcean, Oracle, Firebase, BigQuery, Redshift, DynamoDB, Salesforce.

Team size: 770+ experts.

Top clients: WorldWide Techservices, NP Fulfilment, Jewelex, SettleMint, Havells.

5. Adexin

Adexin is on our list of top-performing providers of supply chain software development services for a data-driven approach to client projects. The company has in its reviews proofs of creating impact on business outcomes, such as improving visibility, accuracy, and operational efficiency, while building solutions that are tailored to unique processes.

In particular, the company’s experts specialize in the cloud-native approach to solution development, ensuring high scalability and seamless integrations. Excellent communication and attention to the tiniest project details have allowed Adexin to win high-profile organizations as its long-term clients.

Services & expertise: AI-driven supply chain software development, MVP development, ERP development, WMS development, IT consulting, digital transformation, CRM development, cloud solutions development.

Technology stack: React Native, Flutter, Swift, Kotlin, Google Maps, Mapbox, Esri, Navigine, OSM, Here, Jest, React, Angular, Tailwind, Three.js, Node.js, AWS, Lambda, Kubernetes, CloudFront, PyTorch, OpenMMLab, ONNX.

Team size: 15+ experts.

Top clients: ITS Astra, eTEU, Green Worldwide Shipping, S1SEVEN, Hailer.

What is Optimization in Supply Chain Management?

Optimization means a company’s continuous adjustment to the changing environment, which is critical to its resilience.

Supply chain optimization means the correct application of delivery processes: the company delivers the correct items to the right place on time and at a reasonable cost.

Sales managers process clients’ orders more effectively. All necessary information about the order is available instantly at all steps.

What is the Importance of Supply Chain Optimization?

Maintaining an optimized supply chain is key in highly competitive markets. Effective operations are essential to keeping pace with developing competitors and changing customer needs.

Businesses address the following challenges with the help of optimization:

Surging costs

Logistics businesses face declining margins due to rising costs and high inflation rates. They must eliminate inefficiencies and cost leaks to provide efficient services and competitive prices.

Labor shortage

Shortage of qualified labor force tops the list of concerns composed by supply chain leaders. Companies investing in supply chain management optimization create more rewarding supply jobs, raising interest among the industry’s top talents.

Sustainability

Efficient supply chain management is essential for coping with uncertainty, emerging gaps, and disrupting challenges. Companies need to increase transparency and ensure suppliers’ compliance for sustainable results.

Fulfillment accuracy

Time to consumers makes the difference between business growth and decline. However, fast order fulfillment is possible with a growing accuracy across the entire supply chain, which stems from optimization.

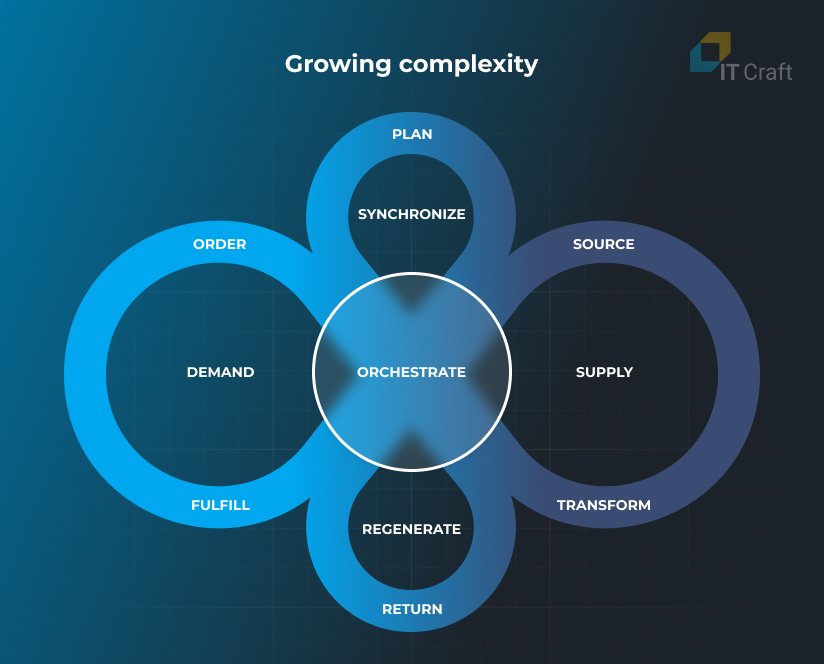

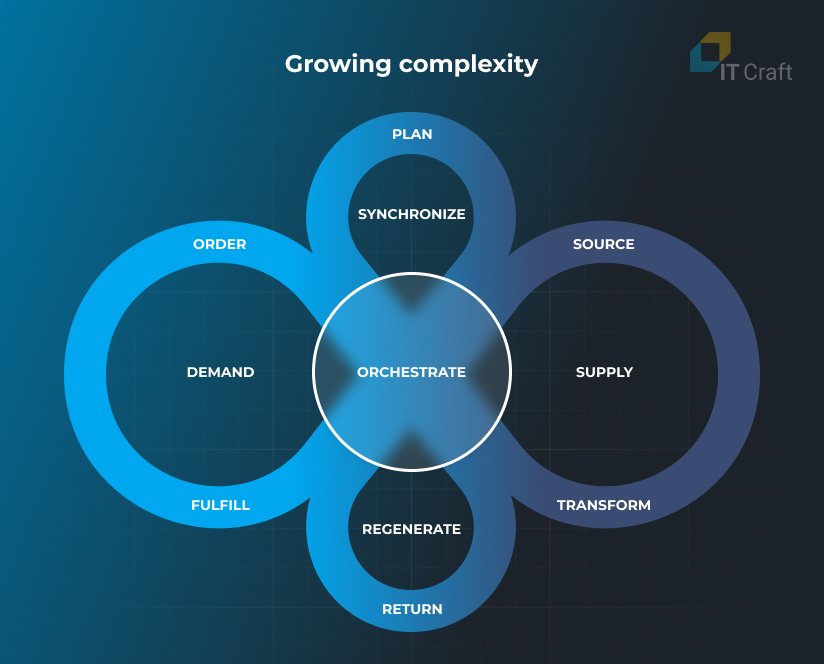

Growing complexity

Only 30% of executives believe their strategy and operations are aligned as they have to, which is no surprise. Companies must orchestrate a growing number of operations across the entire supply chain for efficient order execution.

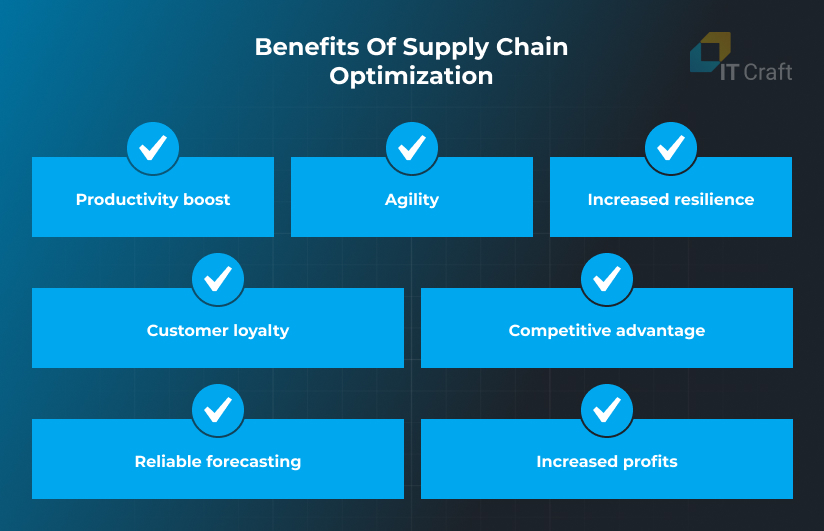

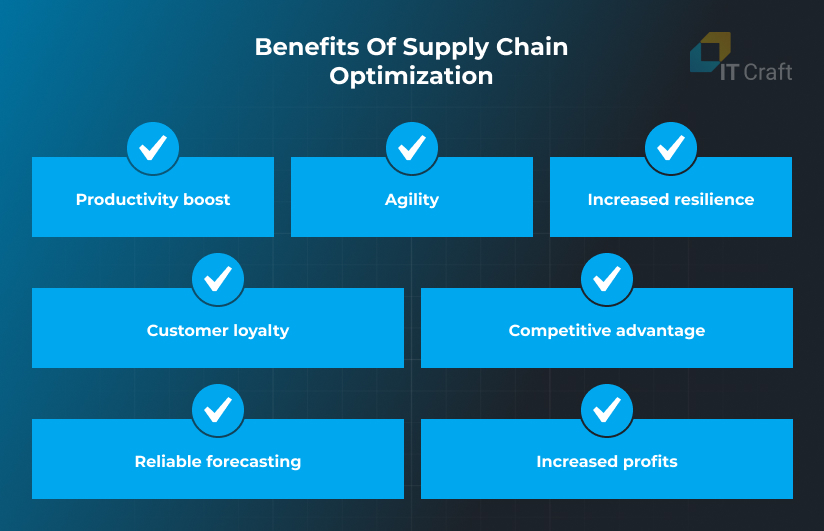

Benefits of Supply Chain Optimization

Supply chain management optimization requires a substantial amount of time and resources. But it always pays off.

For instance, businesses using a TMS can reduce freight expenses by 8%, according to a G2 report. And this is only one of many points where supply chain optimization increases the bottom line!

Further benefits of supply chain optimization include:

Productivity boost

Collaboration improves when a company streamlines operations, aligns the efforts of different departments and increases the visibility of single operations across the system. The team reduces the number of issues that occur and prepares precise schedules.

Agility

Simplified supplier onboarding and collaboration are needed for the company’s flexibility. An agile company requires fewer resources to evaluate and manage new suppliers. It reacts faster to emerging opportunities.

Increased resilience

Management software analyzes supplier relationships: manage agreement terms, identify gaps, or consider relationship prioritizing. Companies become less prone to emerging risks and challenges.

Customer loyalty

To meet the rising bar of customer expectations, positive internal improvements must be part of the plan. They have a direct impact on customers’ decisions.

Competitive advantage

Unique, efficient processes supported by a custom software solution enable companies to take a different position, offering features other companies do not and raising interest from prospective clients.

Reliable forecasting

Historical and real-time data-based reports increase planning accuracy. The company can forecast customer demand, production or delivery time, keep optimum inventory levels, and more.

Increased profits

The end goal of supply chain optimization is profit growth. Companies achieve it by reducing operational costs and growing customer demand.

A transparent spending structure enables companies to identify improvement areas and streamline operating expenses. Reducing supply chain costs from 9% to 4% doubles a company’s profits.

Ten Tips for Optimizing Your Supply Chain Process

Supply chain optimization requires careful improvement on multiple levels, being a mission-critical task. Here are key tips for improving the supply chain:

Tip 1. Focus on the long term

As a business, you must attain long-term sustainability, which is challenging. According to a McKinsey study, only 12% of 56% of organizations that started transformation reached sustainable results for 3+ consecutive years. However, those few achieved 200% revenue growth compared to those who did not.

Top performers use a combination of these three key elements:

- Maintaining implementation rigor at later stages.

- Upgrading and promoting talents.

- Investing in the right resources.

Tip 2. Remember cultural differences

Tight collaboration with suppliers, clients, manufacturers, and service providers is crucial for optimizing supply chain management.

For success, you must keep in mind a variety of cultures and best practices: company, industry, regional, national, and more.

You must manage expectations appropriately to remove invisible communication barriers between you and your partners.

Tip 3. Maintain standards

Clear internal standards, unambiguous onboarding criteria, and measurable KPIs are essential for breaking entry barriers that potential suppliers and prospective clients might face.

Think of developing specific templates and integrating them into your software to track single parameters and properly segment both partners and clients with minimum effort on your side.

Tip 4. Develop an ecosystem

Expanding your software to an ecosystem can make a difference for your partners, eliminating friction across the supply chain.

Think of your business as a software company. Provide fast onboarding and seamless data exchange with partners’ software through API integrations. Think of a special portal containing available resources and documentation. Foster a community.

Tip 5. Reach 100% visibility

72% of companies cannot respond to a breakdown timely due to a supply chain’s limited visibility. They consider lack of transparency a “black hole” that costs profits and decreases partners’ loyalty.

Join the remaining 28%. Build a visible order management system with a focus on resilience. This lets you monitor processes and identify issues before they grow too big.

Tip 6. Upgrade to real-time execution

Real-time order execution is a natural upgrade of a 100%-visible supply chain. It closes the gap between a decision and its execution.

Only 7% of supply chain organizations have a real-time execution system. Yet, they never regret this investment. A real-time execution system enables them to react to changing conditions immediately, thus greatly contributing to supply chain optimization.

Tip 7. Reduce manual processes

Automation enables a company to streamline processes, redistribute workload, and prevent burnout from doing routine tasks. You need no aggressive hiring policy for operations scaling.

Focus on a precise definition of business processes. Introduce improvements step by step. Ensure your team and partners need minimum learning time to start using automation.

Tip 8. Prioritize security

Breaches are catastrophic for logistics companies. They cost organizations over $9.44m on average. Such huge sums arise from lost data, service downtime, employees’ idle time, and regulatory fines.

A successful attack can quickly affect all participants of a supply chain.

You need to identify risks, introduce best security practices across the entire supply chain, e.g., DevSecOps and zero-trust infrastructure, and monitor emerging threats.

Tip 9. Invest in forecasting

Building a demand forecasting system is crucial for supply chain management optimization.

You make data-based decisions. You prevent situations when a warehouse suddenly runs short of stock and the company faces fines for delivery delays.

Certainly, forecasts cannot be 100% accurate. This is why companies prefer adding AI-based functionality that can correct prediction errors.

Tip 10. Do regular audits

Supply chain optimization is a continuous activity.

Schedule system audits for at least every six months. Compare plans and outcomes to introduce further adjustments. Identify possible disruptions to allow preparation time.

Regular penetration testing should also be conducted to identify security concerns. Fix vulnerabilities immediately. Examine your suppliers’ adherence to high security standards.

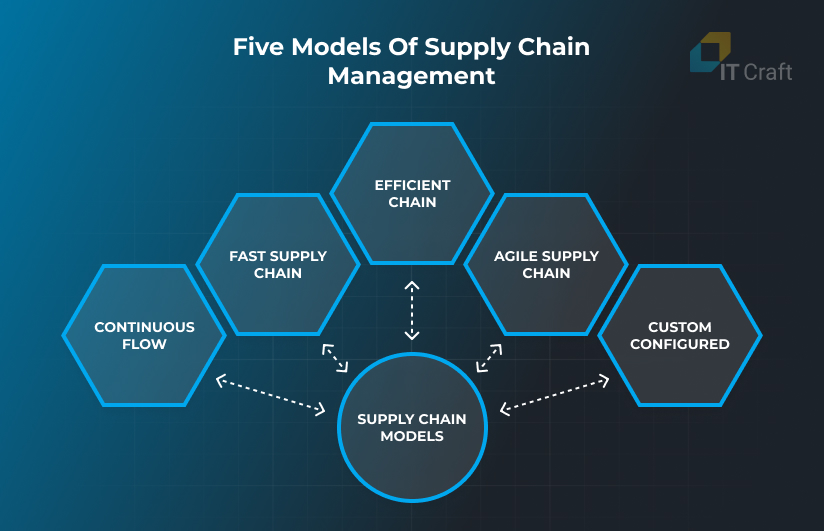

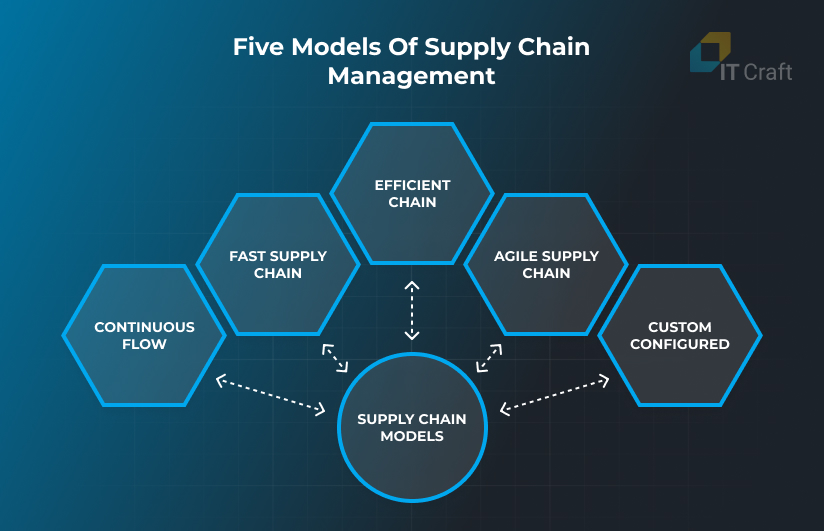

Five Models of Supply Chain Management

Optimization in the supply chain looks different for each business.

Businesses can apply different supply chain management models depending on goals, size, risks, and used software.

Several models exist to cater to different companies’ needs for a smooth flow at the lowest costs. Let’s analyze the most common five:

1. Continuous flow

This traditional model focuses on producing and moving one item at a time as continuously as possible and with little variation.

The continuous flow model loses effectiveness when demand and supply fluctuate, or constant customizations are required. However, it lets businesses reach the best productivity in a stable environment and, as a result, low product prices.

2. Fast supply chain

A fast supply chain focuses on getting a finished product to the market immediately. The companies aim to maximize returns with their help.

This model works best for companies with short product lifecycles. Trendsetters receive a competitive edge by updating and selling their products before demand declines.

3. Efficient chain

An efficient chain model works best for businesses where customer choice is mostly based on the product price. Businesses focus on optimum asset utilization and supply chain to offer the best price.

Businesses use this model to attain a high level of end-to-end effectiveness while operating in markets with severe competition.

4. Agile supply chain

An agile supply chain focuses on fulfilling special orders after businesses receive them from customers rather than selling already-produced items.

Businesses require extra capacity and flexibility to manage large orders and small batches equally effectively. Yet, an Agile supply chain enables businesses to cope successfully with unpredictable market demand.

5. Custom configured

Companies can combine elements from several models to create a supply chain for their goals. Usually, the custom-configured model combines characteristics of continuous and Agile models when both end-to-end production and additional customization are necessary.

The custom-configured model requires an extra initial investment and is complex to scale. However, it works best for small batches and fast turnaround.

!

Conclusion

Now is the best time for your company to adapt to disruptive trends.

Focus on the most important parts of your supply chain optimization plan:

- Prioritize efficiency and resilience.

- Identify risks and opportunities.

- Improve coordination.

- Increase visibility.

- Work on your long-term goals.